FOROP Advanced Materials Co., Ltd.

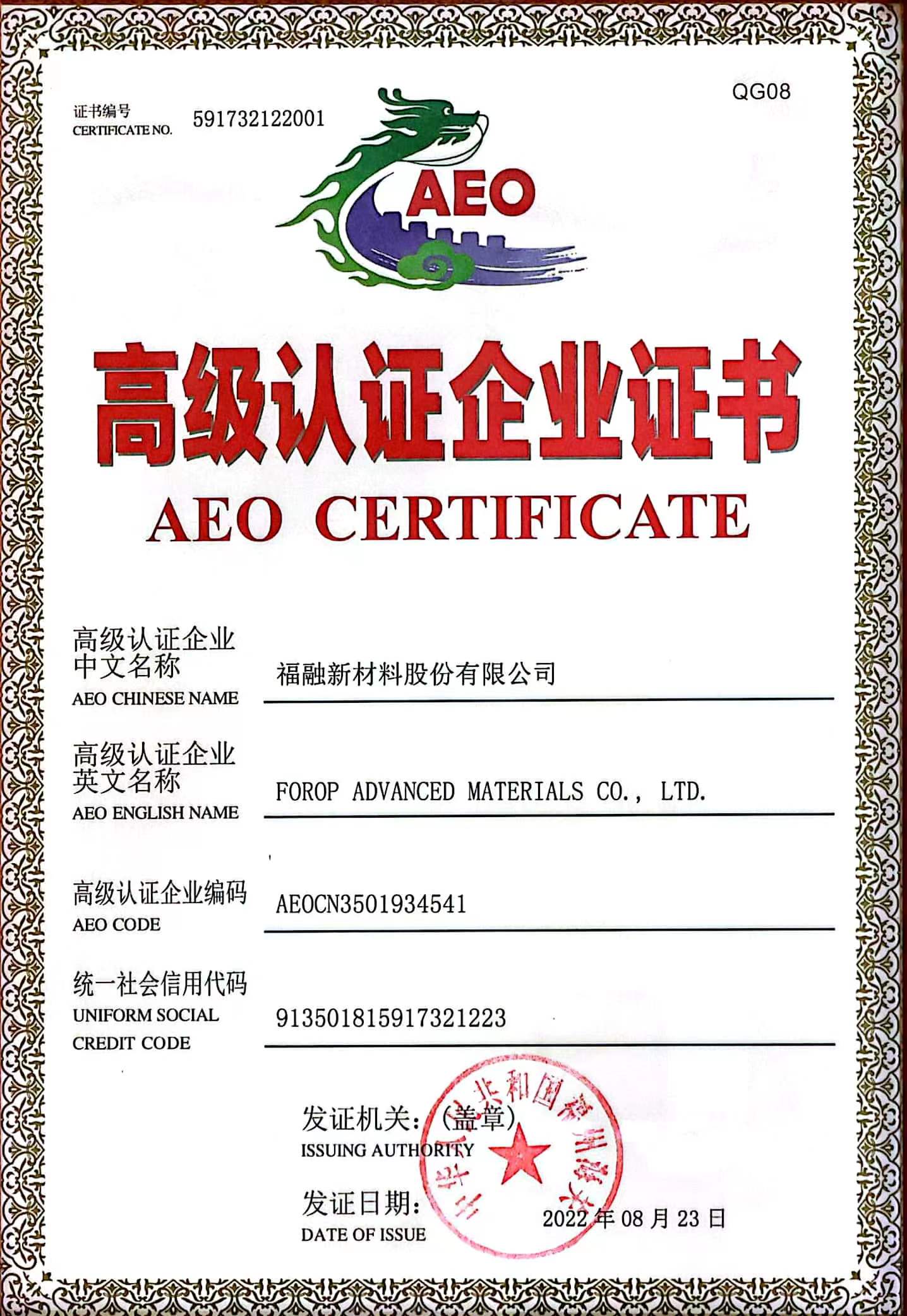

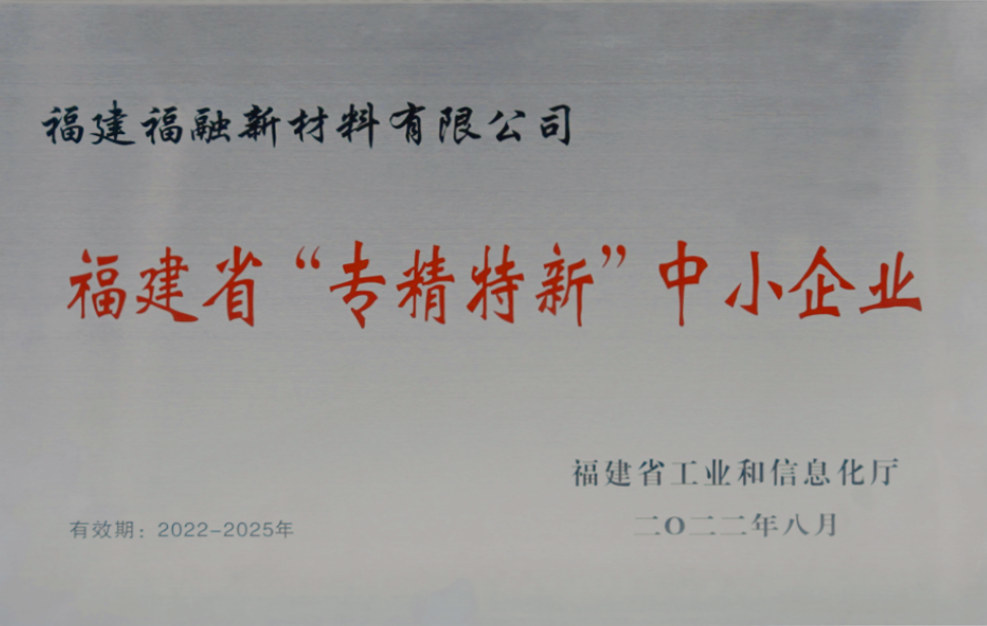

FOROP Advanced Materials Co., Ltd. (hereinafter abbreviated as "FOROP") was founded in 2012 and is headquartered in Rongqiao Economic and Technological Development Zone, Fuqing City, Fujian Province. The company focuses on the R&D, production and sales of polymer films which are widely used in food-grade packaging,daily necessities packaging,pharmaceutical packaging,new energy materials and other fields. The company gains many honorary titles such as National High-tech Enterprise, Customs AEO Senior Certification Enterprise, Fujian Industrialization and Informationization Leading Enterprise, and Fujian "Specialized, High-end and Innovation-driven" Enterprise. The company enjoys great reputation in the world BOPP industry.

At present, the company has five production bases in Fuqing city of Fujian, Nantong city of Jiangsu, Zhaoqing city of Guangdong, Weifang city of Shandong, and Chengdu city of Sichuan. The company equipped 20 cutting-edge film production lines from German Bruckner with the fastest speed of 600m/min. Besides, the company also utilizes the world's most advanced Italian Goebel and German Kampf (Atlas) slitter with the fastest slitting speed up to 1,500m/min. In 2026, the company will have 25 production lines in total, the world's largest scale.

So far, the company's sales network has covered the whole country. Products are exported to domestic and overseas, throughout Asia, Europe, Africa and another three continents, more than 50 countries and regions, in order to meet the growing and changing demands of global customers. In 2021, the company seized the opportunity to successfully develop new 8μm BOPP packaging film, greatly leading the industry's trend of downgauging and environmental protection. For mono- materialization of flexible packaging, the company independently developed BOPE film to achieve recycling. The two knockout products effectively help downstream customers to reduce cost, improve efficiency, conserve energy and reduce consumption.

FOROP adheres to the dual-driven development pattern of “scale efficiency and technological innovation”and continuously deepens the integration of “industrialization + informationization”. Taking“downgauging, functionalization, mono-material, recycling and intelligent manufacturing” as the main line, the company actively explores in the fields of automation equipment, film processing technologies and advanced polymer material application. In order to become a world-renowned leading enterprise in the film industry, the company takes many measures to expand product R&D channels, establishes a sound product matrix, and creates a new service model of“meeting the individual demands of customers”.

Countries and Regions with Sales

Production Bases

20 Existing World-Class Production Lines

Designed Annual Production Capacity

History

Honors

Customs AEO Senior Certified Enterprise

AEO Incubation Demonstration Enterprise

National High-tech Enterprise

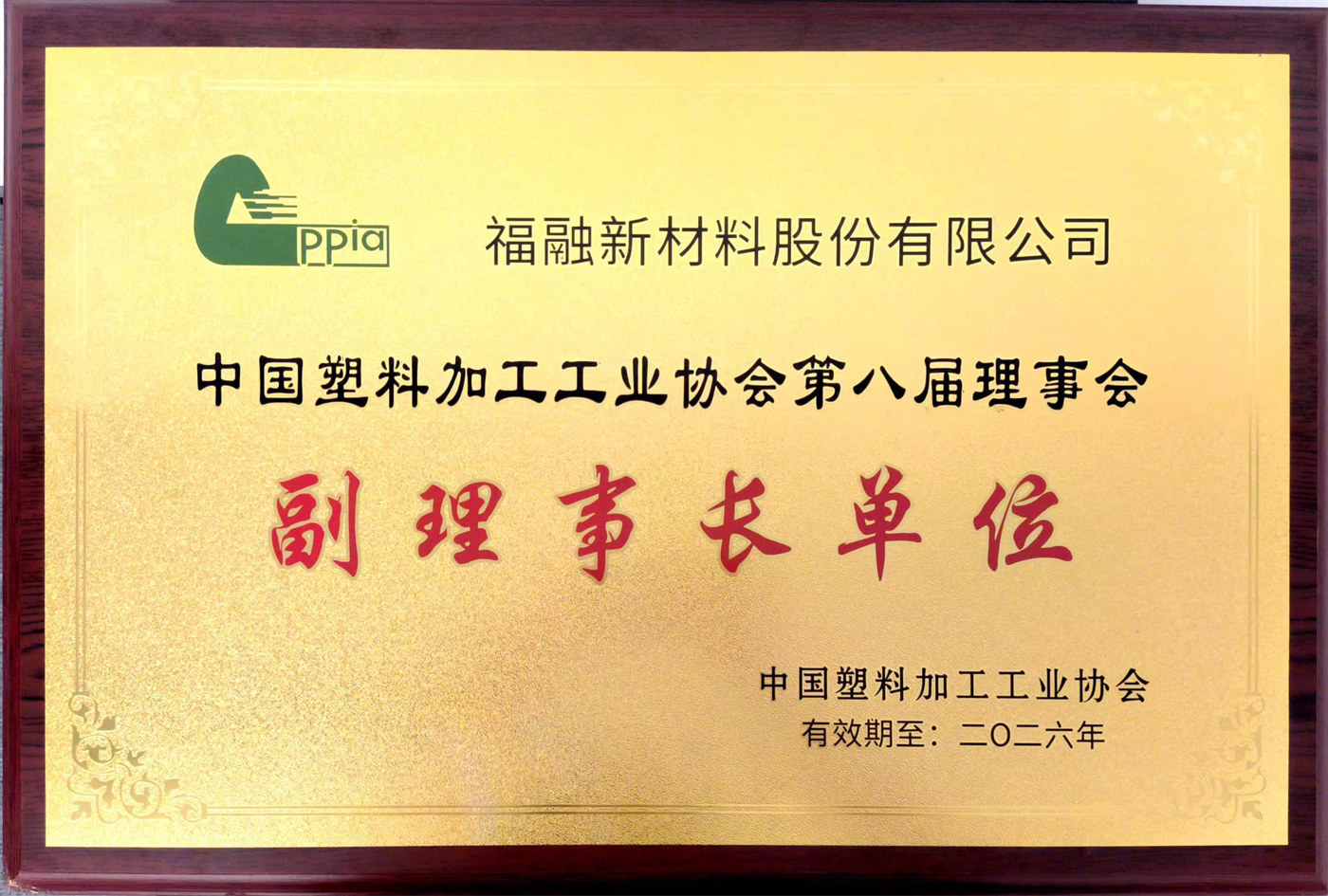

CPPIA — Vice Chairman Unit

"Specialized, High-end and innovation-driven" enterprise

The leading brand in the BOPP film industry awarded by CPPIA

GRS Global Recycled Standard Certification

BRC Global Certification for Food Indrustry

Honor

Customs AEO Senior Certified Enterprise

AEO Incubation Demonstration Enterprise

National High-tech Enterprise

CPPIA — Vice Chairman Unit

Technological Innovation

FOROP Advanced Materials insists on the technological focus and innovative research and development, emphasizes the research and development investments in the film technology field, actively carries out scientific research and has achieved a series of landmark scientific research achievements. At present, FOROP has 20 invention patents, 104 utility model patents and 6 software publications that have been granted. It has become a national new and hi-tech enterprise, one of the specialized and sophisticated SMEs in Fujian Province, and a small giant enterprise of science and technology in Fujian province.

Invention Patents

Utility Model Patents

Software Publications

Furong New Materials Co., Ltd.

Forun New Materials Co., Ltd. (hereinafter referred to as "Forun New Materials") was established in 2012 and is headquartered in Rongqiao Economic and Technological Development Zone, Fuqing City, Fujian Province. The company focuses on the research, development, production, and sales of polymer film materials. Its products are widely used in food packaging, pharmaceutical packaging, daily necessities packaging, and new energy materials. It has won numerous honorary titles, including national high-tech enterprise, customs AEO advanced certified enterprise, Fujian Provincial Industrial and Informationization Leading Enterprise, and Fujian Provincial Specialized, Refined, and New Enterprise. It enjoys a high reputation in the world's BOPP industry.

The company currently has five major production bases in Fuqing, Fujian; Nantong, Jiangsu; Zhaoqing, Guangdong; Weifang, Shandong; and Chengdu, Sichuan. It has introduced 18 globally advanced German Bruckner membrane material production lines. The fastest production line speed can reach 600 meters per minute, equipped with world-advanced Italian Gbel and German Comb/Atlas slitting machines, with a maximum slitting speed of 1500 meters per minute. In the next two years, German Bruckner plans to deliver 10 new production lines successively, and the company's total number of production lines will reach 28, ranking first in the world in scale.

To date, the company's sales network has covered the whole country. The overseas market is based in Southeast Asia and further expands to international markets such as Japan, South Korea, Europe, America, and Africa to meet the growing needs of global customers. The company seized the opportunity and successfully developed the new product 8μm BOPP film in 2021, which greatly leads the industry's lightweight and environmentally friendly trend. It also independently developed BOPE film for the single-materialization of flexible packaging, realizing recycling and reuse. These two "flagship" products effectively help downstream customers achieve the business goals of cost reduction and efficiency increase, energy saving and consumption reduction.

Furong New Materials adheres to the development model driven by both "scale effect and technological innovation", continuously deepening the integration of "industrialization + informatization", taking "lightweight, functional, single material, recyclable, intelligent manufacturing" as the main line, actively exploring in the fields of automation equipment, film processing technology, and advanced polymer material application, adopting multiple measures to expand product R&D channels, establishing a complete product matrix, and creating a new service model "to meet customers' personalized needs", accumulating strength for becoming a globally renowned leader in membrane products!